Extruded Magnetic Strips

- Flexible

-

- Ideal where rigid, brittle or electrically conductive material cannot be used

- Can be manufactured from different compounds to suit desired applications

- Made of compound formulation best suited for extruded shapes

- Delivers maximum flexibility over most comparable magnetic products

- Strength

-

- Formulated to have greater magnetic strength than other thermoplastic materials of comparable flexibility

- The combination of compound and polarity options available allows customization for a wide variety of applications

- Profile

-

- Available in a wide range of shapes and sizes, but without the costly grinding or machining needed with other magnet types

- Standard profile options range in thickness from .030” (.76mm) to .250” (6.35mm) and widths from .250” (6.35mm) to 3.00” (76.2mm). Custom profiles are available upon request

- Can be square-cut or scored to custom lengths based upon your requirements, with or without adhesive. These value added processes are performed in-line for superior quality control

- Can be punched to engineered specifications in a variety of profiles

- Adhesives

-

- Years of experience have gone into the adhesive systems available

- Options include acrylic and rubber based for a wide variety of adhesion solutions to many different of substrates

- Should your application require a special adhesive system, custom systems are available. Technical assistance is available as well.

- Stability

-

- Possesses great stability in elevated temperatures, with only five percent loss in magnetic strength for each 10-degree rise in temperature up to 175 degrees Fahrenheit.

- Shelf Life

-

- Exhibits excellent aging properties during factory storage; resists light and ozone

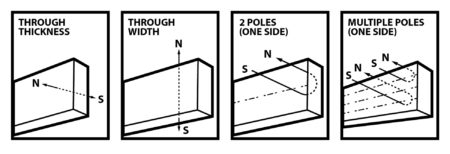

- Pole Arrangements

-